This beginner-friendly guide explains how to use a socket wrench correctly, including choosing the right socket size, proper ratcheting technique, and common mistakes to avoid.

If you are new to the concept of socket wrenches you are in for a very pleasant surprise. There are few other tools that bring you such a sense of accomplishment as when you’ve successfully tightened or loosened a fastener with a socket wrench.

- How to Use a Socket Wrench

- Socket Set Defined

- What is a Socket Wrench?

- How does a Socket Wrench Work?

- What is Torque?

- Recommended Socket Sets for Beginners

- Summary

- Related Posts

How to Use a Socket Wrench

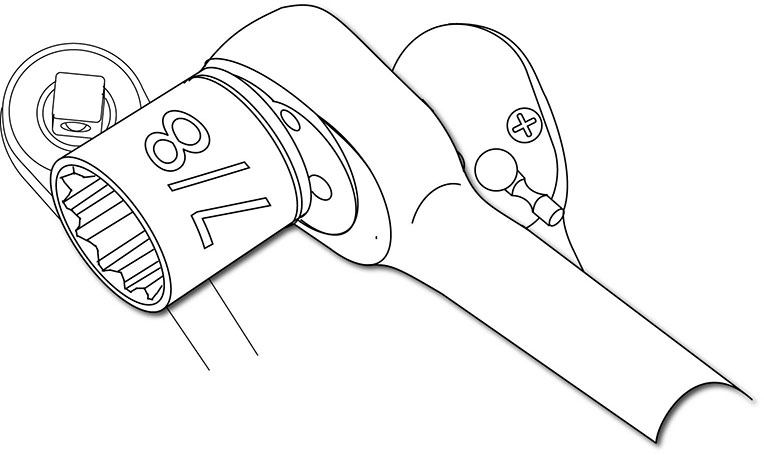

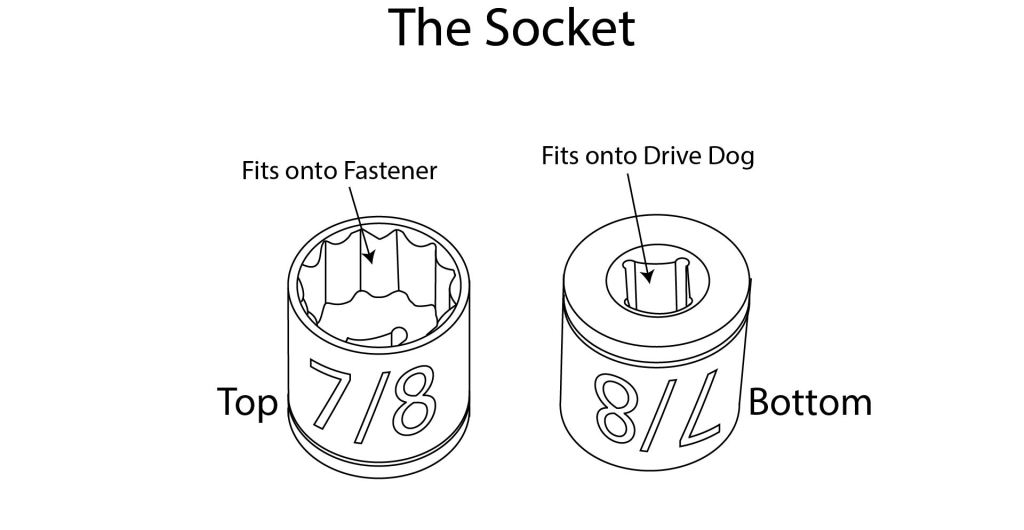

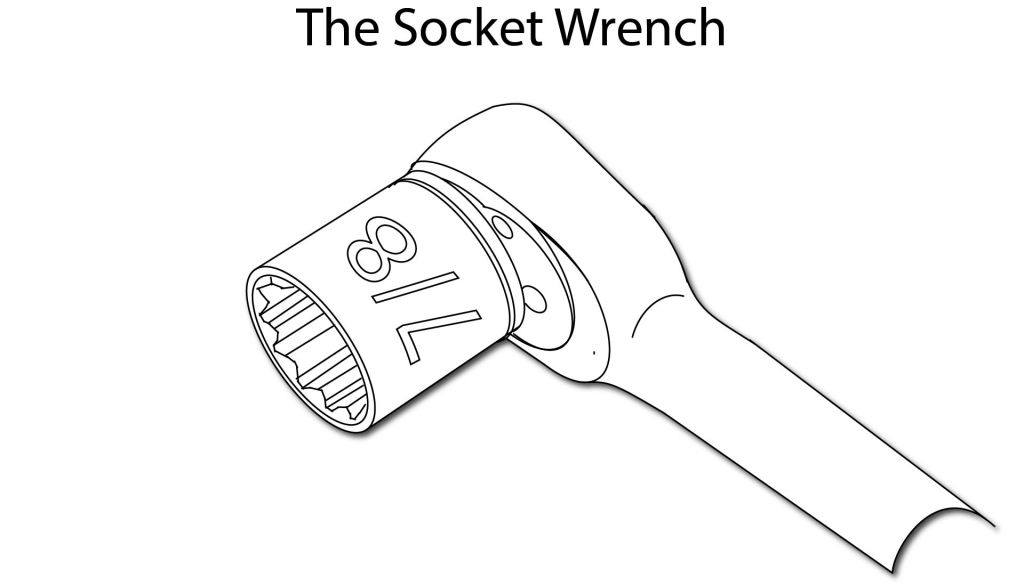

The socket wrench is a two-part device. The socket, the little part, has two holes in it. One is square, the other is hexagonal.

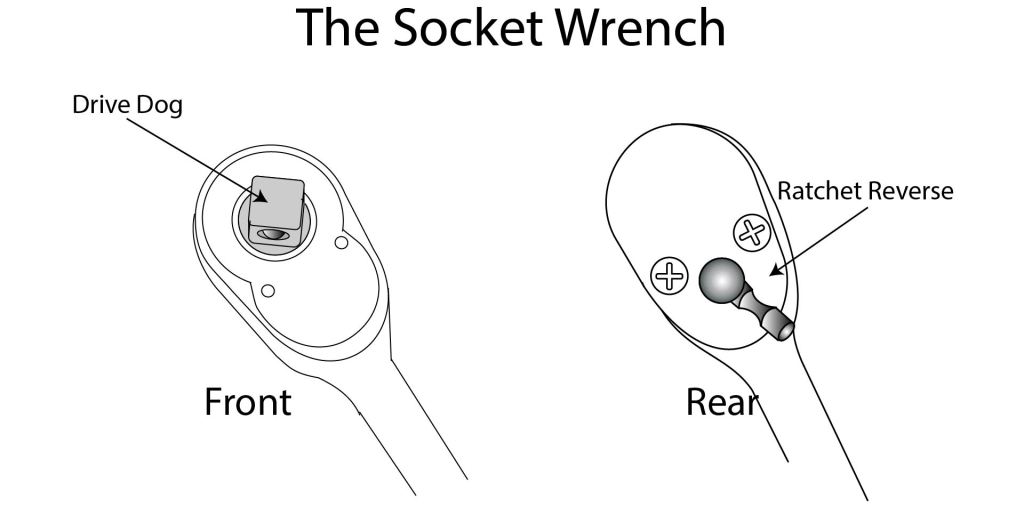

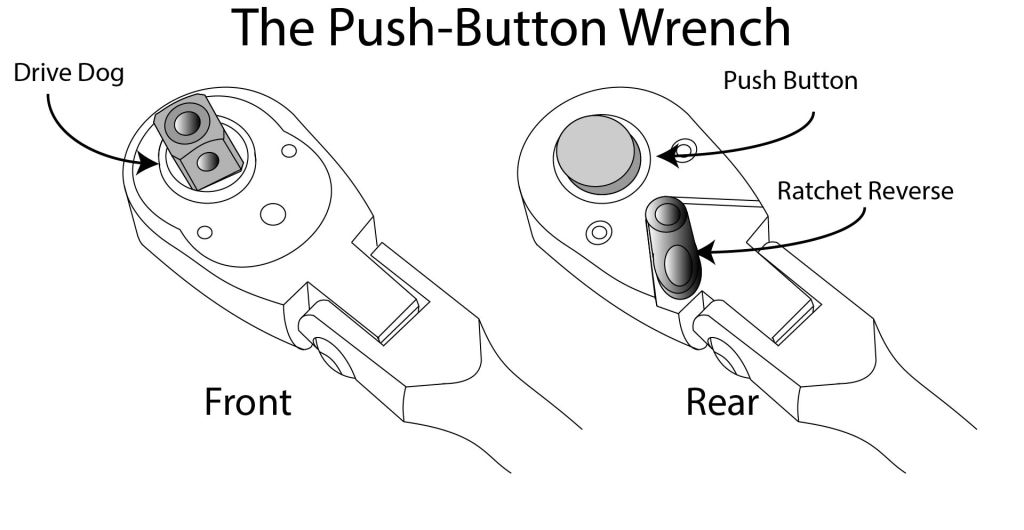

The wrench has a square post, called the drive dog, on the face of it. On the back is a switch that lets you change the wrench’s direction.

Some wrenches have a push-button on the back. You push the button to fit or release a socket from the drive dog.

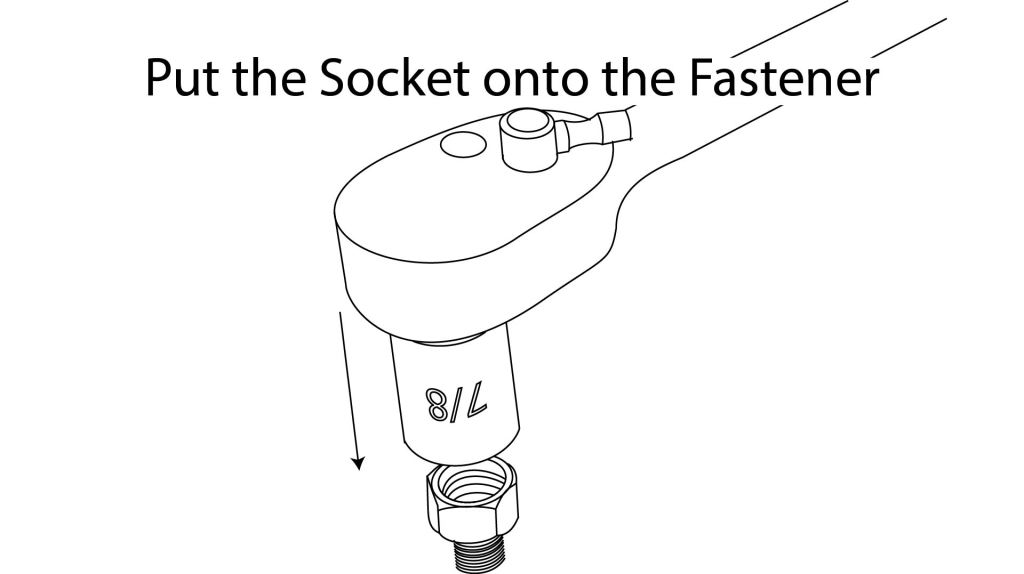

To use a socket wrench, you push the square end onto the square post of the wrench. It will snap into place.

Next, you fit the hexagonal end of the socket onto the fastener – the screw or nut you want to turn.

Then you push or pull the handle to tighten or loosen the fastener. If the wrench is doing the wrong thing, simply slide the little ratchet reverse switch to the opposite side. Now the wrench will do the right thing.

That little ratchet reverse switch connects to a ratchet mechanism inside the wrench that lets it grip the socket in only one direction.

Unlike virtually any other tool, that little ratchet means you never have to remove the tool from the fastener to get a better angle when turning it. Your work is easier and much faster.

Socket Sets Defined

The socket must be the same size as the fastener or it won’t fit. If it doesn’t fit, it can’t work.

Luckily, the sockets are sold in sets, so the chances are highest you’ll find a socket that fits. Luckily, too, those people that manufacture fasteners most often make them in those standard sizes.

The size of the socket is engraved right on the side – 7/8 in our illustrations.

Socket sets can be SAE or metric. An SAE socket will not fit a metric fastener, and vice-versa.

SAE stands for Society of Automotive Engineers, and those sockets come in fractional sizes – ⅛, ¼, ½, etc. Those are fractions of an inch.

Metric sockets are measured in millimeters – 7,8,9,10, etc.

Luckily, socket sets are readily available for each standard and are usually inexpensive.

What is a Socket Wrench?

Good News! The wrench part of most socket sets will fit most socket sets, regardless of measurement standard. That means you can buy one wrench and two sets of sockets and they’ll all work together.

The most common wrench is a ⅜” drive – the drive dog on the wrench is ¾” wide.

Of course, some fasteners are very big, and require much larger sockets. Those fit onto heavy-duty drives with ½” and even 1” drive dogs. But you won’t need those. Equally, little tiny nuts require tiny sockets, and a little ¼” drive to accommodate them.

The truth is that you can get drives in other sizes, but you won’t need them for what you’re working on. Pick up a ⅜” and you’ll be a happy camper.

How does a Socket Wrench Work?

A socket wrench, like any other wrench, is a force-multiplying tool. When you connect it to a fastener, the handle becomes a lever. Ask Archimedes, who said “give me a lever and I will move the world.” Orbital physics aside, the lever is a power tool.

The six sides of the hexagonal socket grip the fastener securely, efficiently transferring the power from the lever to it.

Other wrenches do this, but none with the efficiency of a socket wrench.

What is Torque?

When you push or pull the handle of the socket wrench, you are rotating it around the fastener. The harder you pull, the more rotational energy, or torque, is applied to the fastener. The longer that handle, the more torque is applied.

If you can’t get the fastener to budge, chances are good that you’re not using enough torque.

You could use something called a cheater bar. This is a tube, like a length of pipe, that you put onto the end of the wrench. It makes the handle super long, so that you are applying force far away from the fastener. The longer the cheater bar, the higher the torque you apply to the fastener.

However, with great power comes great responsibility: try not to use a cheater bar unless you have to.

When you screw a nut onto a bolt, the threads on each match up as the nut is seated. When you tighten the nut, you force the threads to merge into each other. This is what tightens the nut onto the bolt.

The more torque you apply, the more the threads are forced together, until, eventually, they form a single piece. If that happens, the nut cannot be removed from the bolt.

This is why you must never use a cheater bar to tighten a fastener: beyond risking the chance of breaking it, an over-abundance of torque can make the fastener impossible to remove.

Recommended Socket Sets for Beginners

Luckily, socket sets are ubiquitous – you can find them online, and at most home improvement, tool, and hardware stores. While prices start around $15 USD for an entry-level set, they can zoom all the way up to over $600 USD for mechanics’ specialty sets.

If you’re planning to use a socket wrench regularly, having a good 3/8″ drive socket set with both metric and SAE sizes will save time and make your work smoother.

View a beginner‑friendly 3/8″ drive socket set on Amazon

(As an Amazon Associate, I earn from qualifying purchases.)

Avoid those inexpensive sets that feature dozens of sockets – the quality will be lower than you need. And avoid those expensive sets that feature exotic metals like titanium. Yes, they’re good sets, but they’ll cost you more than you need to pay and are way too technical for what you need.

Start with a ⅜” drive set, unless you have a specific task that requires a different size.

Summary

According to Wikipedia, although the concept of completely encasing the fastener within the tool dates way back to medieval times, the hexagonal socket wrench that we know and love today has been around since 1863, when it was first patented.

And that is the nuts and bolts of socket wrenches.

Here’s a quick video that shows you a socket wrench in action.

Related Posts

DIY projects involve risk. Always follow manufacturer instructions and use appropriate safety precautions.

7017