Scissors and shears don’t get much respect in the DIY world — until you’re trying to cut something they’re completely wrong for. Then they suddenly matter a lot.

From opening packaging to cutting fabric, insulation, wire ties, or plastic sheeting, choosing the right scissors or shears makes the job easier, cleaner, and safer. This guide explains the different types, what they’re best for, and how to pick the right pair for your DIY toolkit.

Scissors vs. Shears: What’s the Difference?

The terms are often used interchangeably, but there is a difference.

Scissors

- Typically smaller and lighter

- Designed for precision and control

- Best for paper, light plastic, tape, and packaging

Shears

- Larger, heavier-duty cutting tools

- Longer blades and stronger handles

- Designed for tougher materials and repeated use

For DIYers, you’ll likely end up owning both — for very different reasons.

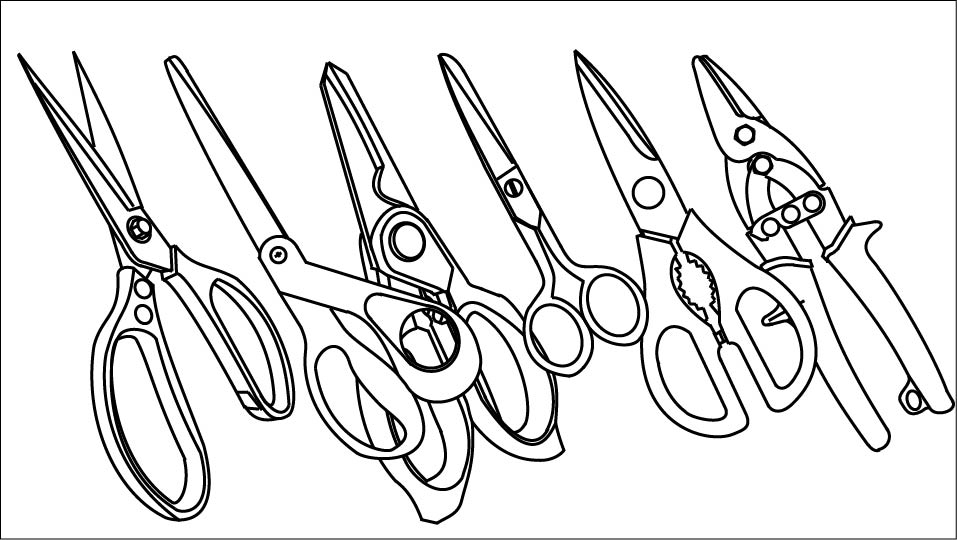

Common Types of Scissors and Shears (And What They’re For)

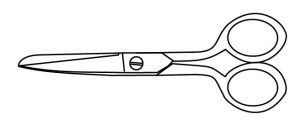

1. Household / Utility Scissors

These are the general-purpose scissors most people already own.

Best for:

- Paper and cardboard

- Packaging

- Tape, twine, and light plastic

Limitations:

- Dull quickly if abused

- Not meant for thick or abrasive materials

2. Heavy-Duty Scissors

A step up from basic household scissors.

Best for:

- Thicker cardboard

- Plastic clamshell packaging

- Light rubber or foam

Why they matter:

- Stronger pivot

- Thicker blades

- Less hand fatigue

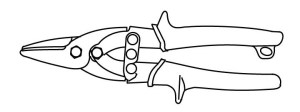

3. Tin Snips / Aviation Snips

Technically shears, these are designed for metal.

Best for:

- Thin sheet metal

- Aluminum flashing

- HVAC ducting

Important note:

- Not a substitute for scissors

- Using them on non-metal materials dulls them quickly

This post tells you everything you need to know about shears: How to Use Aviation Shears

4. Fabric Scissors / Sewing Shears

These are specialized tools — and should be treated that way.

Best for:

- Fabric

- Upholstery materials

- Insulation facing

Rule to live by:

Never use fabric scissors on anything else. Ever.

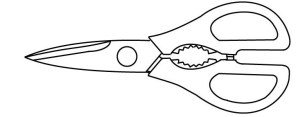

5. Kitchen Shears (Surprisingly Useful)

Kitchen shears often sneak into DIY tasks.

Best for:

- Twine and rope

- Plastic packaging

- Light rubber and foam

Bonus:

- Often have comfortable grips and strong leverage

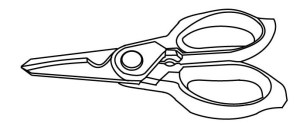

6. Electrician’s Scissors (A Hidden Gem)

These are underrated DIY tools.

Best for:

- Cutting wire insulation

- Electrical tape

- Zip ties

- Light cable work

Why they’re great:

- Short, tough blades

- Excellent control

- Built for abuse

A Solid Starter Pick for DIYers

If you only buy one pair to start, choose a heavy-duty utility shear.

Look for:

- Stainless steel blades

- Comfortable, non-slip handles

- Strong pivot screw

- Ability to cut plastic, cardboard, and light rubber

These durable, highly-rated Heavy Duty Scissors have a great combination of useful features.

(As an Amazon affiliate, I earn from qualifying purchases)

You can always add specialty scissors later as projects demand them.

How to Choose the Right Pair (What Actually Matters)

Blade Strength

- Thicker blades = more durability

- Thin blades = more precision

Handle Comfort

- Ergonomic grips reduce fatigue

- Rubberized handles improve control

Pivot Quality

- A loose pivot causes uneven cuts

- Look for tight, smooth action

Intended Material

- Cutting the wrong material ruins good scissors fast

- Match the tool to the task

Safety Tips for Using Scissors and Shears

Cutting with scissors and shears seem harmless — until it’s not.

- Cut away from your body

- Keep fingers clear of the blade path

- Don’t use scissors as pry tools

- Store them closed or in a drawer

- Never force a cut that feels wrong

Dull scissors slip more than sharp ones — which is how accidents happen.

When NOT to Use Scissors or Shears

Scissors are the wrong tool for:

- Thick metal

- Lumber

- Heavy demolition

- Anything requiring leverage or prying

If you’re forcing the cut, stop and reassess.

Caring for Your Scissors and Shears

A little care goes a long way:

- Wipe blades clean after cutting adhesives

- Tighten the pivot if needed

- Keep specialty scissors separate

- Replace rather than fight with badly damaged tools

Good scissors should cut cleanly — not chew.

Final Thoughts

Scissors and shears may not look impressive, but choosing the right pair saves time, frustration, and injuries. Like most hand tools, they work best when they’re used for exactly what they were designed to do.

Match the tool to the material, and everything gets easier.

Related Posts

- The DIYer’s Toolbox

- How to Safely Use a Utility Knife

- How to Use Aviation Shears

- How to DIY It Safely

DIY projects involve risk. Always follow manufacturer instructions and use appropriate safety precautions.

7030