A good vise doesn’t cut, drill, or fasten anything — it simply holds your work still. And yet, it might be the single tool that most improves accuracy, safety, and confidence in a DIY workspace.

If you’ve ever tried to drill into a spinning board, file something you were gripping with one hand, or tighten a bolt that refused to stay put, you already understand the value of a vise. The trick is choosing the right type of vise for the work you actually do.

What a Vise Really Does (and Why It Matters)

A vise is a fixed clamping tool designed to hold materials securely while you work on them. Unlike clamps, which are often temporary, a vise becomes part of your workspace — a dependable third hand that doesn’t get tired or slip at the wrong moment.

Used properly, a vise:

- Improves precision

- Reduces tool slip

- Makes power tools safer to use

- Frees both hands for better control

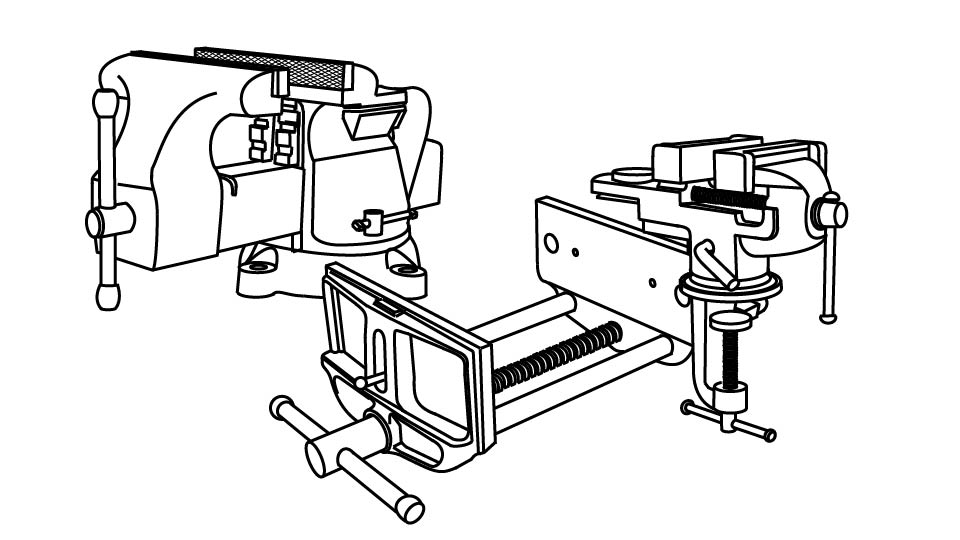

Common Types of Vises (and When to Use Each)

Bench Vises: The All-Purpose Workhorse

A bench vise mounts permanently (or semi-permanently) to a workbench. It’s designed for general DIY and light metalworking tasks.

Best for:

- Filing, sawing, drilling

- Holding metal or wood securely

- General shop work

Look for:

- Cast or forged steel construction

- Replaceable jaw inserts

- A swivel base for flexibility

This highly-rated Bench Vise is a good choice for almost all workshop vise duties.

(As an Amazon affiliate, I earn from qualifying purchases)

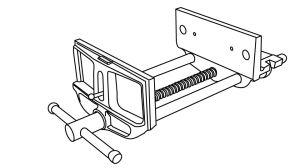

Woodworking Vises: Grip Without Damage

Woodworking vises are designed to hold wood firmly without marring the surface. They often use wide jaws and smoother faces.

Best for:

- Planing, sanding, and joinery

- Holding boards flat or on edge

- Furniture and trim work

Many woodworkers add wooden jaw liners to protect delicate pieces.

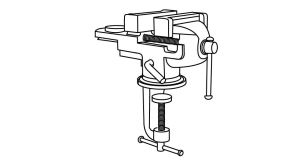

Portable and Clamp-On Vises: Small Space Solutions

If you don’t have a dedicated bench, portable or clamp-on vises offer surprising versatility. They attach temporarily to tables or work surfaces and store easily.

Best for:

- Apartments and small garages

- Occasional DIY projects

- Light-duty holding tasks

They’re not as rigid as bench vises, but they’re far better than trying to improvise.

Specialty Vises (Worth Knowing About)

- Drill press vises for precision drilling

- Machinist vises for metalworking accuracy

- Panavise-style vises for electronics and small parts

You don’t need these starting out — but it helps to know they exist.

Key Factors When Choosing a Vise

Jaw Width and Opening

A wider jaw spreads pressure evenly, while a larger opening handles thicker materials. Bigger isn’t always better — choose what matches your typical projects.

Mounting Style

- Permanent mounting = maximum stability

- Clamp-on mounting = flexibility

If the vise moves, it not only defeats the purpose, it can also become a safety threat.

Build Quality

A vise should feel boringly solid. Avoid lightweight castings that flex under pressure. Slop in the screw or jaws is a red flag.

Replaceable Jaws

Hard jaws are great for metal; soft jaws protect wood and finished surfaces. Replaceable inserts give you both.

Vise Safety Basics (Often Overlooked)

- Don’t overtighten — crushing your work helps no one

- Keep fingers clear when tightening (duh)

- Never use a vise as an anvil unless it has an anvil built into it. Then ONLY use that anvil surface, and respect the strength of the bench below the vise.

- Secure the vise firmly before applying force

A vise is a safety tool — treat it like one.

When a Vise Beats Clamps (and When It Doesn’t)

A vise is ideal when:

- The work stays in one place

- You need repeatable accuracy

- You’re using hand or power tools nearby

Clamps still win for:

- Large panels

- Irregular shapes

- Temporary positioning

Most workshops eventually use both.

Bottom Line

The right vise turns frustration into focus. It doesn’t speed you up — it slows the chaos down so you can work deliberately and safely.

Choose a vise that fits your space, your projects, and your patience level. Once you have one, you’ll wonder how you ever worked without it.

For a broader look at how vises fit into a beginner’s tool setup, see our guide to The DIYer’s Toolbox.

DIY projects involve risk. Always follow manufacturer instructions and use appropriate safety precautions.

7047